What is Self-Adhesive Film | Benefits and Applications

Self-adhesive films; simple and practical surface protection

Table of Contents

What Are Self-Adhesive Films? Self-adhesive films are thin polymer or plastic layers coated with a pressure-sensitive adhesive (PSA) that adhere to surfaces without heat or additional tools.

Their main advantages include easy application, clean removal, and reliable surface protection during production, transport, and installation.

By preventing scratches, dirt, and damage, self-adhesive films help maintain product quality and customer satisfaction.

Structure and Components of Self-Adhesive Films

Base Film Layer

The base film may be made from polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), or polyester (PET).

Each material offers specific benefits: PET for clarity and strength, PE for lightweight and cost-effectiveness, and PP for balanced flexibility.

In some applications, multi-layer films are used to combine durability with flexibility for higher performance.

Adhesive Layer

The adhesive layer can be acrylic, silicone, or rubber-based. Acrylic adhesives provide long-term stability, silicone adhesives are suitable for delicate or high-temperature surfaces, and rubber adhesives offer high initial tack.

Choosing the right adhesive depends on surface type, environmental conditions, and required protection period.

High-quality adhesives also ensure clean removal without residue or surface damage.

Protective Liner

Most self-adhesive films include a liner that prevents accidental sticking and enables precise cutting or die-cutting.

The liner protects the adhesive during storage and handling and improves film application accuracy.

Selecting the proper liner ensures the film remains effective until installation.

Key Features of Self-Adhesive Films

Ease of Use

Self-adhesive films are designed for quick and simple application.

They require no special tools, heat, or solvents—just a clean surface for bonding.

This convenience reduces installation time, labor costs, and improves production efficiency.

Clean Removal

High-quality self-adhesive films can be removed cleanly without leaving sticky residues or damaging the surface.

This feature is critical in industries such as automotive, electronics, and home appliances.

Products remain clean, scratch-free, and visually appealing when delivered to customers.

Resistance to Environmental Factors

Many films offer resistance to UV light, temperature changes, moisture, and chemicals.

This durability ensures surfaces remain protected during storage, transport, or outdoor exposure.

Films with special additives provide longer service life in industrial or construction environments.

Applications of Self-Adhesive Films

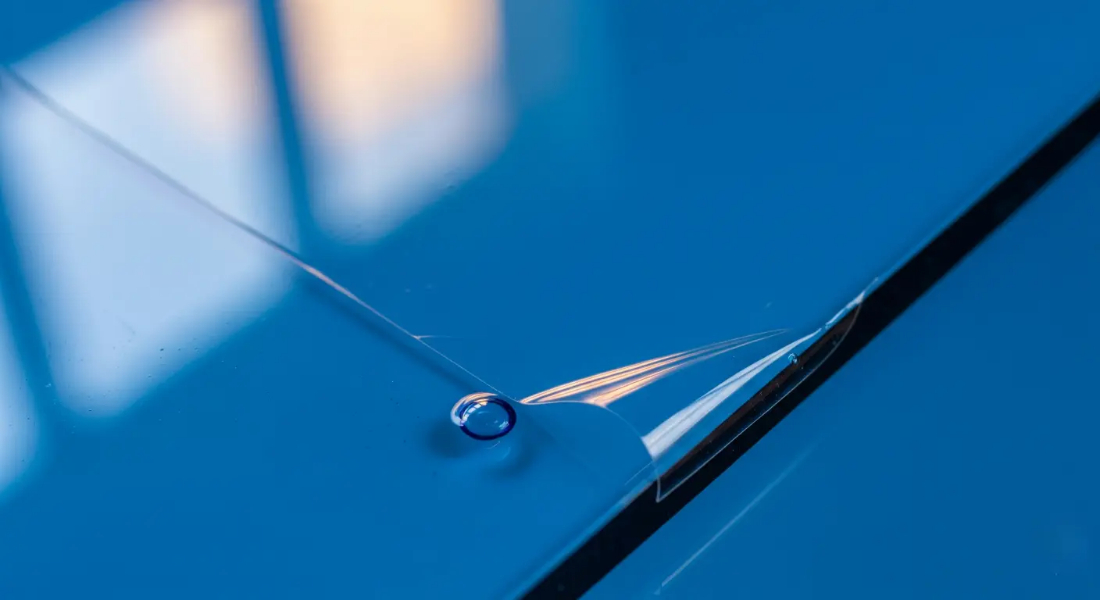

Construction and Glass Industry

Self-adhesive films protect aluminum profiles, glass panels, and composite sheets during building projects.

They safeguard surfaces from scratches, cement splashes, and dust until project completion.

After removal, surfaces remain clean and ready for final use.

Home Appliances

Appliances such as refrigerators, washing machines, and ovens use self-adhesive films to keep surfaces intact until customer delivery.

They prevent dust, stains, and scratches, ensuring the appliance arrives in showroom condition.

This also boosts efficiency on production lines with easy application and removal.

Automotive Industry

In the automotive sector, films protect painted parts, dashboards, trims, and headlights.

They prevent scratches during assembly, transport, and showroom display.

Self-adhesive films also reduce warranty claims and improve customer trust.

Benefits of Using Self-Adhesive Films

Surface Protection and Product Quality

Self-adhesive films act as a protective barrier against scratches, stains, and impact.

They maintain the original appearance of the product and reduce costly rework or repairs.

This protection helps manufacturers deliver products in perfect condition to customers.

Cost Reduction and Economic Savings

By minimizing surface damage and reducing rejected items, self-adhesive films lower production costs.

Their fast installation and easy removal save time and labor in production lines.

The overall result is higher efficiency and improved profitability for businesses.

Enhanced Customer Experience

Clean, damage-free products create a positive brand image and increase customer satisfaction.

The use of self-adhesive films ensures that final products look professional and premium.

This benefit leads to stronger customer loyalty and improved competitiveness in the market.

Categories of Self-Adhesive Films

By Film Type

Self-adhesive films are available in PE, PP, PVC, and PET materials.

PE is lightweight and affordable, while PET offers superior strength and clarity.

Each type is selected based on surface needs, cost, and durability requirements.

By Adhesive Type

Adhesives may be acrylic, silicone, or rubber-based.

Each adhesive type provides unique benefits in terms of tack, temperature resistance, and long-term performance.

Proper adhesive selection ensures strong adhesion and easy removal.

By Surface Energy

High-energy surfaces (like glass or metals) require moderate adhesives, while low-energy plastics may need stronger adhesives.

This classification ensures proper bonding without residue.

How to Select the Right Self-Adhesive Film

Surface Type

Smooth surfaces like glass and metal require moderate adhesives, while textured plastics may need stronger bonds.

Choosing the right adhesive prevents film lifting and ensures clean removal.

Environmental Conditions

For outdoor use, films with UV resistance and weather durability are essential.

Moisture-prone environments benefit from water-resistant films.

Duration of Protection

Short-term films are designed for temporary storage and transport.

Long-term films last several months and are suitable for construction and assembly processes.

Standards and Quality Testing

Adhesion Testing

Standards like ASTM D3330 are used to evaluate peel strength and clean removal.

Testing ensures reliable performance in real-world conditions.

Environmental Resistance Testing

Films undergo tests for UV, temperature, humidity, and chemical resistance.

This guarantees that selected films maintain quality in demanding environments.

Frequently Asked Questions (FAQ)

Do self-adhesive films leave residue?

High-quality films remove cleanly without leaving sticky residues.

Testing the film on a small area before full application ensures safe removal.

What is the difference between short-term and long-term films?

Short-term films are designed for temporary protection, while long-term films last months and protect surfaces during assembly or construction.

Are self-adhesive films safe for sensitive surfaces like car paint?

Yes, special low-tack adhesives are designed for delicate surfaces, ensuring damage-free protection.

How can I extend the lifespan of a self-adhesive film?

Proper storage away from direct sunlight, moisture, and chemicals extends film life.

Installing on clean, smooth surfaces also ensures better adhesion.

Are self-adhesive films recyclable?

Many films are recyclable, especially mono-material PE or PP films.

However, adhesives and liners may require special recycling processes.