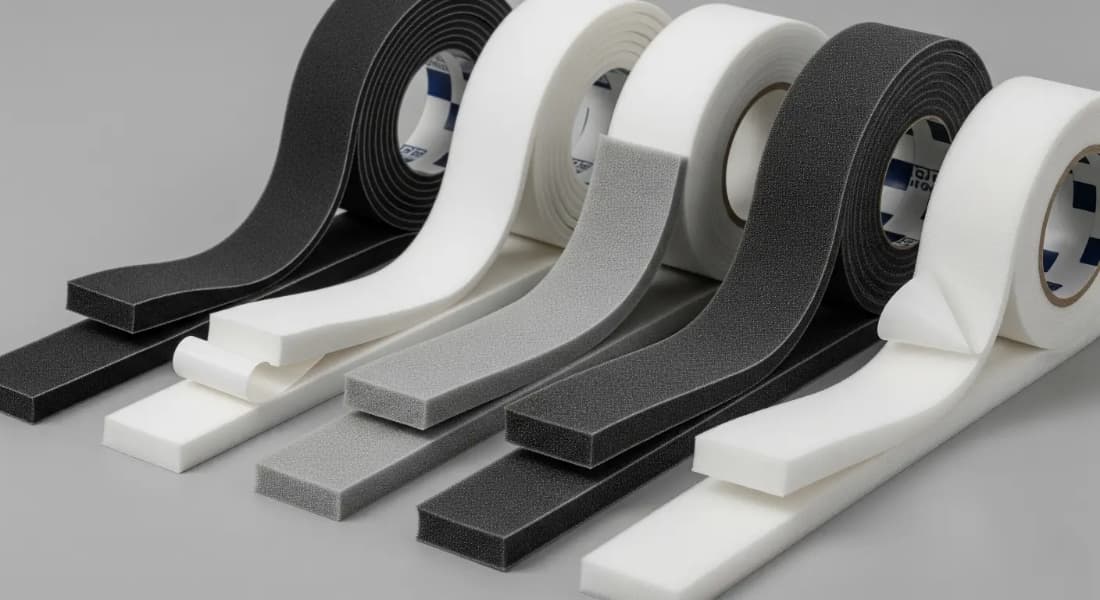

Foam Edge Guards | Reliable Protection for Corners and Edges

High-durability foam strips, an ideal choice to prevent impacts, scratches, and enhance safety in your space.

Table of Contents

what are Foam protection tapes? Foam protection tapes are rolls or cut pieces of engineered foam usually coated with pressure-sensitive adhesive (PSA). These tapes are used for surface protection, shock absorption, sealing, and noise reduction during manufacturing, packaging, and installation.

Composition and Materials

Foam Types

PE Foam: Polyethylene foam has a closed-cell structure and low weight, suitable for insulation, cushioning, and moisture resistance.It is widely used in household packaging and sheet protection and offers good durability for indoor applications.

EVA Foam: EVA foam is more elastic and resilient, ideal for fitting curved surfaces and absorbing momentary impacts.It is commonly used where precise fitting and soft contact are required.

EPDM Foam: EPDM offers excellent resistance to ozone, sunlight, and weather, making it suitable for exterior applications and automotive sealing.It provides long-term performance for building façades and exterior weatherstrip.

NBR/CR Foam: Nitrile and chloroprene foams resist oils and chemicals, suitable for industrial environments.Using NBR/CR reduces the risk of corrosion or damage in oil or fuel contact.

PU Foam (Polyurethane): PU foam is soft and energy-absorbing, ideal for point impact cushioning.

It is used where a combination of softness and high energy absorption is needed.

Adhesive Layer and Liner

Acrylic adhesive is popular for UV stability and clean release, suitable for glass and coated metal surfaces.This type of adhesive remains stable under temperature changes and usually leaves no residue after removal.

Rubber adhesives provide stronger initial tack for textured or powder-coated surfaces.They offer rapid grip on non-smooth surfaces but may not be ideal for delicate substrates.

Paper or silicone-coated liners protect the adhesive and enable precise die-cutting. Proper liners improve cut quality and durability, essential for customized tape shapes.

Performance Additives

UV stabilizers help foam resist sunlight and extend outdoor lifespan.They prevent yellowing and preserve mechanical properties when exposed to solar radiation.

Antistatic additives reduce dust attraction, critical in electronic assembly lines.By reducing surface static, appearance and cleanliness during assembly and packaging are improved.

Surface scratch inhibitors or lubricants reduce friction and prevent micro-scratches.This is particularly important for glossy panels in appliances or colored parts.

Benefits and Value Proposition

Surface Protection and Product Quality

Foam tapes prevent scratches, abrasion, and surface impact, keeping the appearance intact until delivery.

This directly lowers return rates and post-production repair or polishing costs.

Sealing and Noise/Vibration Reduction

Due to their cellular structure, foam tapes absorb vibration and noise and act as gaskets or seals.

In automotive and household applications, this improves user experience and reduces impact noise.

Quick Installation and Cost Savings

PSA adhesives enable installation without complex tools, reducing assembly time.

This saves labor costs and minimizes waste, lowering overall production and packaging expenses.

Applications and Compatible Surfaces

Glass

Low Tack is recommended for PMMA and PC to prevent clouding or residues after removal.

Household Appliances

Foam tapes protect appliance panels from scratches and maintain product integrity until delivery.

Automotive and Transportation

Foam tapes reduce interior noise, seal doors, and protect trim components.

Painted and Specialty Surfaces

Powder-coated surfaces require sufficient tack to adhere without lifting corners.

Plastic, and Composites

In ACP and other composites, foam strength prevents warping or damaging printed layers.

Exhibition Stands

For exhibition stands, quick installation and clean removal reduce maintenance and repair costs.

Foam Tape Classification

Based on Foam Material

Classification by foam type (PE, EVA, EPDM, NBR, PU) simplifies proper selection.

Each material has specific advantages and limitations that should match project requirements.

Based on Adhesive Type and Tack Level

Low / Medium / High Tack selection is based on the surface energy of the substrate to balance adhesion and clean release.

Initial testing on the actual surface ensures no residue or tape lifting.

Based on Functionality

Tapes can be designed as UV resistant, scratch-resistant, antistatic, or thermal/acoustic insulating.

This categorization ensures suitability for environmental conditions and production processes.

Technical Specifications and Key Tests

Thickness, Density, and Hardness

Common thickness ranges from fractions of a millimeter to several millimeters depending on foam type and application.

Density and hardness determine cushioning, resilience, and compressive strength.

Adhesion and Clean Release

Peel 180° per ASTM D3330 is the standard for clean release assessment and should be tested on actual samples.

Following manufacturer datasheets and practical testing prevents residue or breakage during production.

Temperature Resistance and Environmental Stability

Operating temperature ranges vary by foam and adhesive, typically 0–80°C.

For outdoor or industrial applications, UV, ozone, and high-temperature resistant grades should be selected.

Selecting the Right Foam Tape

Substrate and Surface Energy

The substrate (metal, plastic, coated, or glass) determines adhesive type and tack level.

Always test adhesion on an actual sample before production to ensure clean removal and strong initial grip.

Environmental Conditions and Residence Time

For direct sunlight or high humidity, UV/stable or water-resistant grades are recommended.

Residence time is crucial; follow manufacturer datasheets for optimal performance.

Subsequent Processes

If the part undergoes pressing, bending, or cutting, the foam must have sufficient elasticity and thermal stability.

Proper matching between foam choice and subsequent processes prevents delamination or adhesive transfer.

Comparing Common Foams for Protective Tapes

EVA vs PE

EVA is softer and more flexible, suitable for precise fitting and cushioning applications.

PE offers better resistance to moisture and chemicals, ideal for sealing and long-term protection.

Why EPDM for Outdoor Use

EPDM naturally resists UV and ozone, ensuring stable performance outdoors.

This makes EPDM a reliable choice for building and automotive weatherstrips.

Blends and Compounds

Neoprene/EPDM blends combine the advantages of both materials, offering multi-functional performance.

These blends are suitable for applications requiring both mechanical and environmental stability.

Proper Installation and Guidelines

Surface Preparation

Clean the surface of oil, dust, and silicone to maximize adhesion and clean release.

Use compatible solvents and lint-free cloths for improved installation quality.

Dry and Wet Installation Techniques

Dry installation with a roller or squeegee is suitable for most substrates and ensures uniform adhesion.

Wet installation is used mainly on certain glass surfaces and requires full drying before handling.

Preventing Bubbles and Wrinkles

Work from the center outward to remove trapped air and prevent wrinkles.

For large parts, segmenting and controlled overlap ensures quality and alignment.

Sustainability and Recycling

Material Choice and Recyclability

Single-material constructions improve recyclability and simplify recovery processes.

Designing for end-of-life reduces environmental impact and disposal costs.

Waste Reduction and Disposal Cost

Using rolls with optimized widths and accurate die-cutting minimizes material waste.

Proper waste management strengthens sustainability while reducing disposal expenses.

Standards and Quality Requirements

Adhesion Testing per ASTM D3330

Peel tests at 180°/90° are standard for evaluating adhesion and clean release.

Testing on actual samples ensures correct grade selection and minimizes production issues.

Traceability and Documentation

Recording dimensional, peel, and environmental tests per batch enables quality tracking.

Traceability accelerates complaint resolution and increases industrial client trust.

Frequently Asked Questions

What is the difference between EVA and PE foam?

EVA is softer and more conformable, suitable for cushioning and curved surfaces.

PE is more resistant to moisture and chemicals, ideal for sealing and long-term protection.

Which foam is best for outdoor use?

EPDM is ideal due to its excellent resistance to UV, ozone, and environmental conditions.

It performs better than other foams for building façades and automotive weatherstripping.

What TACK is needed for textured surfaces?

High Tack is usually recommended to ensure penetration and adhesion to textured surfaces.

For sensitive surfaces, start with Low Tack and adjust after testing.

How to prevent adhesive residue after removal?

Select the correct adhesive grade and follow recommended residence time.

Conduct Peel tests on actual samples and adjust installation conditions for clean removal.