Secure and Professional Packaging with Shrink Film

Shrink film is a modern solution to protect products and enhance packaging appeal.

فهرست مطالب

What Are Shrink Films? Shrink film is an advanced polymer product used for packaging various items. With its elasticity and high protective properties, this film enhances product durability and optimizes packaging.

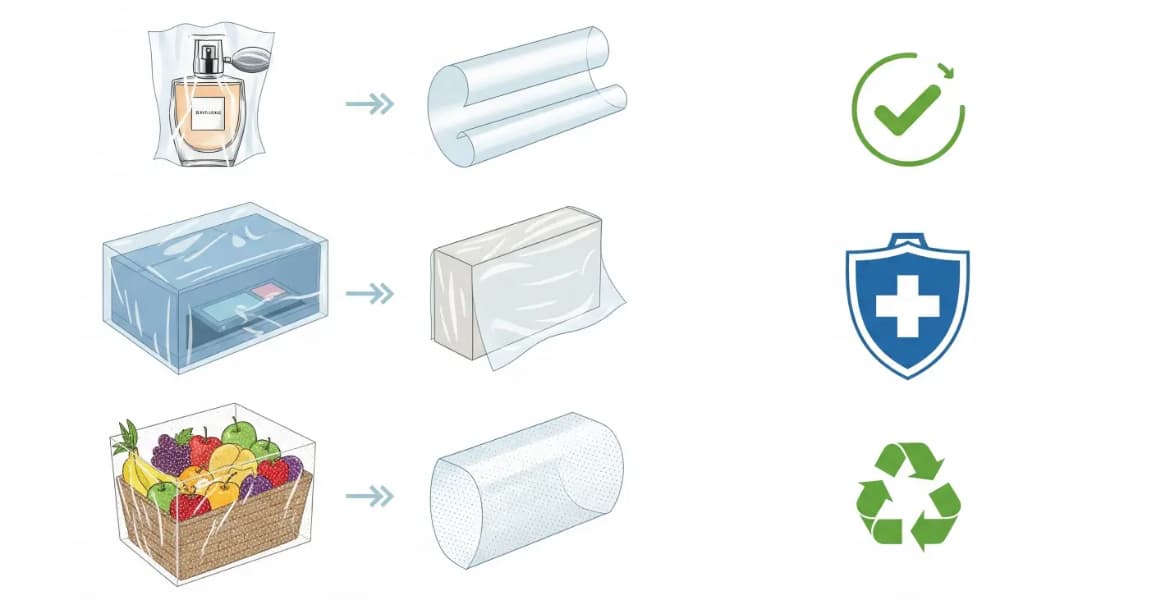

Shrink Film and Its Applications

Product Protection

Shrink film creates a tight, protective skin around goods, shielding them from dust, moisture, and scuffs during handling.

Its conforming wrap stabilizes multipacks and prevents items from shifting or falling apart in transit.

The result is fewer damages, cleaner presentation, and stronger customer confidence at unboxing.

Applications in Food and Industrial Packaging

In food packaging, shrink film preserves freshness, reduces oxygen ingress, and supports tamper evidence.

For industrial goods, it cushions finishes and keeps surfaces clean—ideal for appliances, components, and hardware.

Across retail, pharmacy, and e-commerce, it streamlines bundling, display, and inventory control.

Key Features of Shrink Film

Flexibility and Elasticity

Engineered for high elasticity, shrink film adapts to irregular shapes without wrinkling.

Its controlled shrink ratios let you dial in tightness for trays, bottles, or carton bundles.

That flexibility cuts secondary materials and keeps pack presentation consistent.

Tear and Environmental Resistance

Quality films deliver tear resistance, impact absorption, and durable seal integrity.

Formulations withstand temperature and humidity swings, maintaining tension over time.

This resilience protects goods through warehousing, shipping, and shelf display.

Clarity and Shelf Appeal

High-clarity films showcase the product while enabling scannable barcodes and labels.

A smooth, glossy finish elevates brand perception and attracts attention on the shelf.

Options for printable or pre-printed films add storytelling without extra labels.

Benefits of Using Shrink Film

Increased Durability and Shelf Life

A tight wrap reduces mechanical abrasion and micro-contamination points.

For perishables, barrier variants can slow moisture and oxygen exchange.

Together, these effects extend shelf life and reduce returns due to damage.

Packaging Process Optimization

Shrink film supports high-speed lines, from L-sealers to tunnel systems.

Fast sealing and reliable hot-slip properties keep uptime high and jams low.

You gain cycle-time improvements, lower labor, and repeatable, audit-ready results.

Lower Logistics and Transport Costs

Tight bundles create denser loads and better cube utilization on pallets.

Less secondary packaging means lighter shipments and simplified recycling.

Fewer damages and returns translate into lower total landed cost.

Choosing the Right Shrink Film

By Product Type and Pack Size

Match thickness (gauge) and shrink force to product weight and fragility.

Light items prefer thinner gauges; heavier packs may need reinforced films.

Consider package geometry, hole punch patterns, and venting for steam or gases.

Compliance with Safety and Hygiene Standards

For food and pharma, select materials that meet relevant safety and hygiene norms.

Verify migration, odor, and seal strength performance under real conditions.

Documented compliance eases market access and builds buyer trust.

For guidance and placing an order, contact us

Advanced Options for Performance

Multilayer Constructions

Multilayer shrink films combine layers for strength, clarity, and sealability.

You can tune slip, anti-fog, and barrier properties for specific channels.

This engineering delivers consistent wrapping at lower material weights.

Printed and Branded Shrink

Custom printing turns each pack into media, adding brand impact and anti-tamper cues.

Registration accuracy and heat stability keep artwork crisp after shrinking.

It’s a cost-effective route to premium shelf presence without extra cartons.

Sustainability Considerations

Lighter gauges and recyclable polymers reduce footprint without losing protection.

Design for mono-material streams to simplify post-consumer recovery.

Optimized yields and fewer damages support lower lifecycle emissions.

Implementation Tips for Operations Teams

Equipment and Line Settings

Align sealing temperature, dwell time, and tunnel heat to the specific film.

Keep film path tension even to avoid dog-ears, fish-eyes, or weak seals.

Routine checks on knives, belts, and tunnel curtains preserve consistency.

Quality Control and Testing

Track shrink force, seal strength, and dart impact at startup and changeovers.

Use retention samples and visual AQLs to catch drift early.

Data-driven adjustments ensure stable specs across large runs.

When to Choose Shrink Film Over Alternatives

Pick shrink when you need unitization, visibility, and speed in one step.

Compared with cartons or stretch wrap, it offers tighter display and less material.

For premium retail packs, shrink balances protection, branding, and cost.

Summary

Shrink film is a versatile, high-clarity packaging solution that enhances protection, speeds operations, and lowers logistics costs.

With the right gauge, shrink profile, and compliance, brands unlock reliable performance from line to shelf.

Thoughtful selection and control turn shrink into a scalable, export-ready packaging platform.